Hi

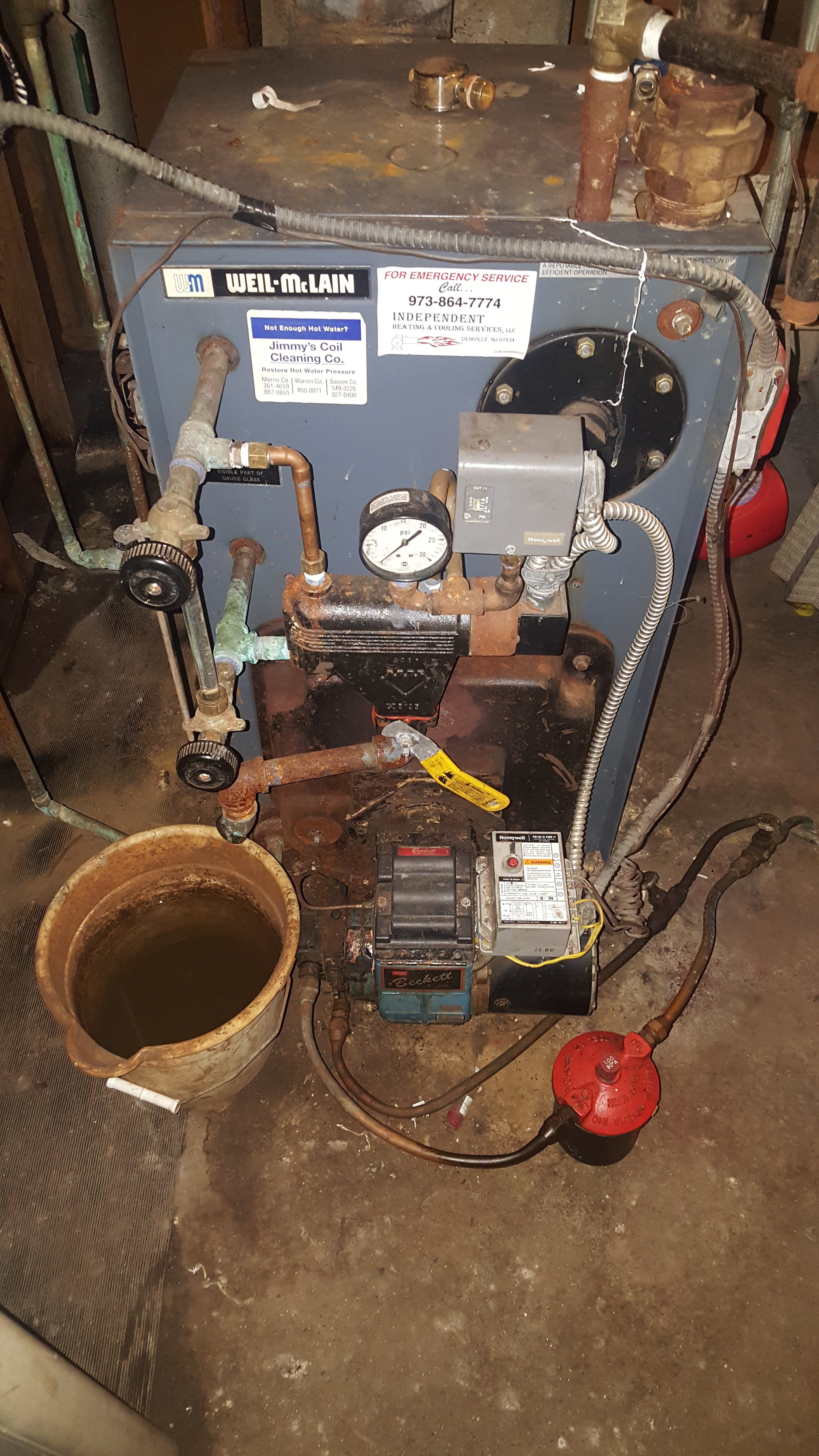

Can someone tell me why I cant get a few Beckett AfG burners with Honeywell 7184B Primary control combination to fire when I bring 120 Volts directly to the white and blk.( Iam trying to change the blast tube and end cone using the same burner chassis for a different boiler) When I do this the steady green light comes on which means burner on while nothing is happening. I have tt jumped out. When I do this with Riello Burners and carlin Burners they fire right up. What am I missing? All the burners were working when I pulled them off boilers to change them to gas burners

I have attached some pics

Thanks

Joe

HHI Services

![]()

![]()

Can someone tell me why I cant get a few Beckett AfG burners with Honeywell 7184B Primary control combination to fire when I bring 120 Volts directly to the white and blk.( Iam trying to change the blast tube and end cone using the same burner chassis for a different boiler) When I do this the steady green light comes on which means burner on while nothing is happening. I have tt jumped out. When I do this with Riello Burners and carlin Burners they fire right up. What am I missing? All the burners were working when I pulled them off boilers to change them to gas burners

I have attached some pics

Thanks

Joe

HHI Services